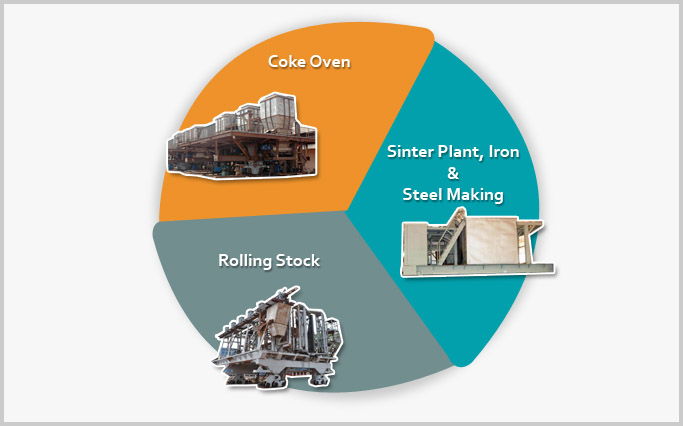

Metallurgical Equipment

Coke Oven Machines on Turnkey Basis

As an emerging global specialists in supplying complete range of Coke Oven Servicing Machines, Bhilai Engineering Corporation engineered technology offers state-of-art Machines for Coke oven Complex, large or small.| Range of Machines | Coke Oven Battery Size | Unit Weight of Machines | Brief Scope of Work |

4.3 meter to 7.0 meter |

87 MT to 150 MT | a) Design, Manufacture, Supply, Erecting, Testing, Trial Run, Commisioning, Establishing Performance Gurantee. b) Including Electrical System, drive automation, handling facilities, Instrumentation, automation, intercommunication, interlocking, air-conditioning, ventilation, pollution control measures & illumination. |

|

4.3 meter to 7.0 meter |

240 MT to 380 MT

|

||

4.3 meter to 7.0 meter |

80 MT to 200 MT

|

||

4.3 meter to 7.0 meter |

67 MT to 80 MT

|

||

4.3 meter to 7.0 meter |

37 MT to 40 MT

|

Coke Dry Quenching

- Self propelled coke car

- Hot coke bucket car

- Hoist and transfer car

- Coke charging devices

- Coke discharging devices

Functional Specifications of Coal Charging Car

- Open coal tower gates

- Close coal tower gates

- Travel to the oven to be charged & centre

- Remove all charging hole lids

- Lower all telescopes

- Charging hole/ lid cleaning

- Open/Close the gates & stop/start screw feeders

- Raise all telescopes

- Replace charging hole lids

- Mortar preparation & luting charging hole lids

- Repeat cycle

Functional Specifications of Coke Pusher Car

- Travel the machine to Oven & Centre

- Engage door extractor with the door, lift & remove oven door to cleaning position

- Push the red hot coke out of the oven into the Coke Quenching Car through Coke Guide Car on the discharge side of battery

- Clean Oven Door & Door Frame

- Replace Oven Door

- Open the Leveler Window, level the coal charge in the oven, clean leveler window frame,& there after close the leveler window

- Collect splillage during leveling,& door extraction operation in to a hopper & dispose off the same in to the skip hoist bunker

- Cycle time will be equal or less than 11 minutes

Functional Specifications of Coke Guide Car

Travel to the oven to be pushed & center the door extractor

Travel to the oven to be pushed & center the door extractor

- Engage door extractor & remove the door

- To engage coke guide in the oven to be pushed

- Engage guide cage to receive coke. Slew oven door to cleaning position & clean the door

- Guide hot coke to coke quenching car during pushing operation

- Disengage Coke Guide

- To engage frame cleaner/ door extractor on the oven

- Clean door frame

- Repeat the cycle

Functional Specifications of Quenching Car & Electric Loco

- Waiting near the oven to be pushed

- Receiving the hot coke from the oven

- Transportation of hot coke to quenching tower

- Transport & discharge quenched coke on to the coke wharf

- Travel to the next oven in the battery to be pushed

- Positioning of the quenching car along the oven to be pushed

|

|

|

|

|

|

|

|

Sinter Plant, Iron & Steel Making

- Sinter Machines

- Pallet Assembly

- Sinter Cooler

- Wind Boxes and Down-comers

- Blast Furnace and Stove Shells

- Bell–less Top Structure

- Dewatering Drum Assembly

- Mud gun Assembly

- Small Bell/Large Bell Hopper

- Tuyere Stock Assembly

- Equipments for Slag House

- Grab Bucket Assembly

- Top Cone Material Hopper

- Top Charging Equipments

- Axial Cyclone

- Teeming Ladle

- Hot Metal Ladle

|

|

|

|

|

|